Lead Acid Battery Recycling Plant

SMELTING

REFINING

Refining operation is a Pyrometallurgical process, carried out in kettles of capacities of 25 MT or 40 MT. Metals like copper, tin, arsenic and bismuth are removed from the hard Lead to manufacture pure Lead. Purity of Lead achieved is 99.97 %( Min).

Turnkey Solutions For Battery Recycling Plant. ACS Provides Environmentally Sound Technologies For Lead Smelting and Refining

Equipment For Old Lead Recycling Plant

- Battery Cutting Machines

- Furnace feeding systems

- Lead Rotary Furnace

- Pollution Control Equipments for Lead Processing

- Lead Refining and lead alloying plant

- Lead Ingot Casting Machine

- Lead Ingot Stacking Machine

- Oxy-Fuel heating systems

- Effluent Treatment plant

- Lead Pump

- Battery Crushing And Separation Unit

Ingot Casting Machine

Furnace Feeding System

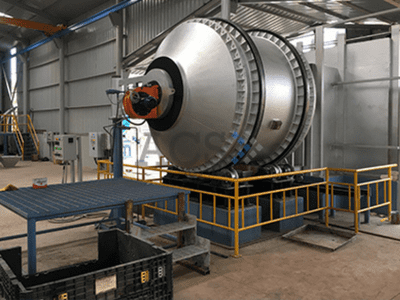

Rotary Furnace with Fugitive System

Refining And Alloying Pots

Rotary Furnace With Refractory Bricks

Pollution Control Equipments for Lead Refining

Battery Crushing And Separation System

The plant consist of :

Crusher with feeding system, Sink and Float system consisting of Stainless Steel tanks. The scrap battery is crushed in the hammer and the output is passed through a sieve conveyor to wash off and separate the Lead Oxide powder. After this Lead and plastics are separated in sink and float tanks. The PP and PE are also separated in the last tank. The whole system is closed loop, and the water is re-circulated after passing through a filter press. An acid neutralization system is also used to treat the water before re-circulation.

Battery Crushing And Separation System